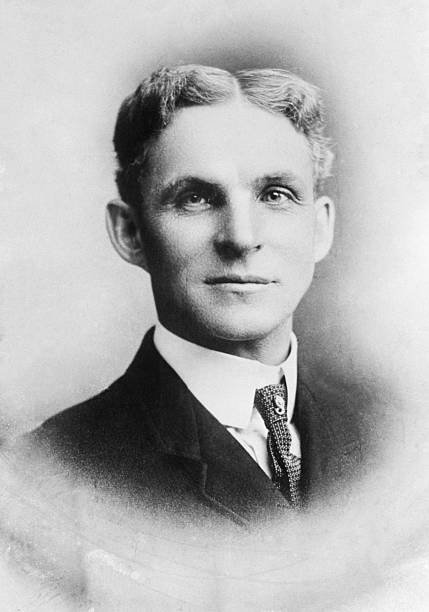

Henry Ford (1863–1947) was an American industrialist and founder of the Ford Motor Company, renowned for revolutionizing the automobile industry with the introduction of mass production techniques. Born in Dearborn, Michigan, Ford is best known for developing the Model T, an affordable and reliable car that made personal transportation accessible to the masses. He pioneered the use of assembly line manufacturing, which significantly reduced production costs and increased efficiency, transforming not only the automotive industry but also industrial practices worldwide. Ford’s innovations extended to his labor practices, including the introduction of the $5 workday in 1914, which doubled the average wage and reduced employee turnover. His approach to business and manufacturing had a lasting impact on both the economy and industrial operations, cementing his legacy as a key figure in the development of modern industry and consumer culture.

Early Life and Background

Henry Ford was born on July 30, 1863, in Greenfield Township, Michigan, on a prosperous farm owned by his parents, William and Mary Ford. His father, William, was of Irish descent, while his mother, Mary, had Belgian roots. Ford was the eldest of six children in a family that adhered to the values of hard work, thrift, and self-sufficiency typical of rural America during that period. These values would shape Ford’s character and influence his later business practices.

From a young age, Ford exhibited a keen interest in mechanics and machinery. Unlike most children of his time, who might have been more concerned with farm chores or schoolwork, Ford was more interested in understanding how things worked. His early fascination with mechanics began when he disassembled and reassembled watches, an activity that earned him a reputation as the local watch repairman. His practical experience on the farm, where he often worked with farm machinery, deepened his mechanical skills.

Ford’s formal education was limited. He attended a one-room schoolhouse where he received a basic education in reading, writing, and arithmetic. However, he found little interest in academic subjects and was more drawn to working with his hands. This disinterest in formal schooling led him to leave school at the age of 16 to seek work in Detroit, a city that was rapidly industrializing and offered more opportunities for someone with his mechanical inclinations.

In 1879, Ford took an apprenticeship as a machinist with James F. Flower & Bros., a machine shop in Detroit. This was a pivotal period in his life, as it exposed him to the latest technological advancements in machinery and manufacturing. He later worked at the Detroit Dry Dock Company, where he continued to develop his skills. These early experiences in Detroit’s industrial environment laid the groundwork for Ford’s future endeavors in the automotive industry.

Detroit, during the late 19th century, was a bustling industrial hub, and Ford found himself in the midst of a technological revolution. The city was home to numerous factories and machine shops, which were at the forefront of innovation in manufacturing. Ford was particularly fascinated by steam engines, which were then the most advanced form of power for machinery. His exposure to this technology fueled his desire to create machines that could ease the burdens of manual labor and revolutionize transportation.

In 1882, after completing his apprenticeship, Ford returned to the family farm. However, his passion for mechanics and innovation was too strong to be confined to farm life. He continued to work on mechanical projects in his spare time, often experimenting with engines and machinery. In 1888, Ford married Clara Ala Bryant, and they moved to Detroit permanently. The couple had one son, Edsel Ford, who would later play a significant role in the Ford Motor Company.

Ford’s return to Detroit marked a turning point in his life. He took a job as an engineer with the Edison Illuminating Company in 1891, where he quickly rose through the ranks due to his technical expertise and innovative thinking. Working at Edison provided Ford with the opportunity to meet and learn from some of the most brilliant engineers and inventors of the time, including Thomas Edison himself. Edison’s approach to innovation, which focused on practical solutions to real-world problems, deeply influenced Ford’s own philosophy.

During his time at Edison, Ford began experimenting with gasoline engines, a relatively new technology that had the potential to revolutionize transportation. He saw the limitations of steam engines and recognized that gasoline-powered engines could be more efficient and practical for personal transportation. In 1896, Ford completed his first experimental vehicle, the Quadricycle. The Quadricycle was a simple, four-wheeled vehicle powered by a two-cylinder gasoline engine. It was crude by modern standards, but it represented a significant step forward in automotive design and demonstrated Ford’s potential as an innovator.

The success of the Quadricycle convinced Ford that there was a future in the automobile industry. However, his path to success was not immediate. His first two attempts to establish a car manufacturing business, the Detroit Automobile Company and the Henry Ford Company, were unsuccessful. These early ventures failed due to a combination of financial difficulties, disagreements with investors, and the high cost of production. Despite these setbacks, Ford remained undeterred and continued to refine his designs and improve his engineering skills.

By the early 1900s, Ford had developed a reputation as a talented and innovative engineer, which attracted the attention of investors who were willing to back his third attempt at starting an automobile company. In 1903, with the financial support of several prominent investors, Ford founded the Ford Motor Company. This time, his efforts were successful, and the Ford Motor Company quickly became one of the most successful and influential car manufacturers in the world.

Rise of the Ford Motor Company

The founding of the Ford Motor Company in 1903 marked the beginning of Henry Ford’s journey to becoming one of the most influential figures in the automotive industry. The company was established with an initial investment of $28,000 from a group of twelve investors, including Ford himself. Ford held a modest 25.5% stake in the company, but his role as vice president and chief engineer gave him significant influence over its operations and direction.

The Ford Motor Company’s early years were challenging, but Ford’s vision and determination drove the company forward. One of Ford’s key insights was the need to produce a car that was affordable, reliable, and easy to maintain. At the time, automobiles were largely luxury items, accessible only to the wealthy. Ford believed that if he could produce a car that was within the financial reach of the average American, he could tap into a vast, untapped market and fundamentally change the nature of personal transportation.

The company’s first car, the Model A, was introduced in 1903. It was a modest success, selling nearly 1,700 units in its first year. However, Ford was not satisfied with the Model A’s performance and cost. He continued to experiment with new designs, constantly seeking ways to improve efficiency and reduce costs. Ford’s relentless pursuit of innovation led to the development of several more models over the next few years, each incorporating new features and improvements.

Ford’s breakthrough came in 1908 with the introduction of the Model T, also known as the “Tin Lizzie.” The Model T was designed to be a simple, affordable, and durable car that could be mass-produced. It featured a 20-horsepower, four-cylinder engine and was capable of reaching speeds of up to 45 miles per hour. The car’s high ground clearance made it suitable for the rough, unpaved roads that were common in rural America, and its simple design made it easy to repair and maintain.

What set the Model T apart from other cars of the time was its affordability. When it was first introduced, the Model T was priced at $850, a fraction of the cost of other automobiles on the market. Over the next few years, Ford implemented a series of cost-cutting measures and innovations in manufacturing that allowed him to continually reduce the price of the Model T. By 1916, the price had dropped to $360, making it affordable to millions of Americans. This dramatic reduction in price was made possible by Ford’s revolutionary use of the assembly line in manufacturing.

The concept of the assembly line was not new, but Ford’s implementation of it in the production of the Model T was groundbreaking. In 1913, Ford introduced a moving assembly line at his Highland Park plant in Michigan. The moving assembly line allowed workers to remain stationary while the car chassis moved along a conveyor belt, with each worker responsible for performing a specific task. This innovation dramatically increased the speed and efficiency of production, reducing the time it took to assemble a Model T from 12 hours to just 93 minutes.

Ford’s use of the assembly line revolutionized manufacturing and set a new standard for industrial production. It allowed the Ford Motor Company to produce cars at an unprecedented scale, meeting the growing demand for affordable automobiles. By 1914, Ford was producing more than 300,000 Model Ts per year, accounting for nearly half of all cars sold in the United States. The success of the Model T made Ford a household name and established the Ford Motor Company as the dominant player in the automotive industry.

Ford’s success was not just the result of technological innovation; it was also driven by his unique approach to business. Ford believed in paying his workers well and implemented the $5 workday in 1914, doubling the average wage for factory workers at the time. This move was controversial, but it had several benefits. It reduced employee turnover, increased productivity, and allowed Ford workers to afford the very cars they were producing. Ford’s belief that well-paid workers were more productive and loyal helped create a stable and motivated workforce, contributing to the company’s success.

The rise of the Ford Motor Company had a profound impact on American society. The Model T brought automobile ownership within the reach of the average American family, transforming personal transportation and changing the way people lived and worked. The car gave people greater mobility, allowing them to live farther from their workplaces and travel more easily. It also contributed to the growth of the suburbs and the expansion of the American road network.

By the 1920s, the Ford Motor Company had become a global enterprise, with factories and assembly plants in countries around the world. The Model T was sold in more than 60 countries, making it the first truly global car. Ford’s success also inspired other manufacturers to adopt his methods, leading to the widespread adoption of the assembly line in industries beyond automotive manufacturing.

Innovations and Contributions to the Automobile Industry

Henry Ford’s impact on the automobile industry is perhaps best encapsulated by his relentless drive to make cars affordable and accessible to the masses. His innovations transformed not only how cars were made but also how industries approached manufacturing and labor. Ford’s most famous contribution, the moving assembly line, is often credited with bringing about the modern era of mass production, but his influence extends far beyond this single innovation.

The introduction of the moving assembly line at the Highland Park plant in 1913 was a monumental shift in manufacturing. Before Ford, cars were built by teams of skilled workers who assembled each vehicle from start to finish. This method was labor-intensive, slow, and expensive, making cars luxury items accessible only to the wealthy. Ford’s assembly line changed all of that. By breaking down the manufacturing process into simple, repetitive tasks, Ford was able to significantly reduce production time and costs. The time it took to assemble a Model T dropped from over 12 hours to just 93 minutes, and the cost of production fell accordingly. This innovation was not just about speed; it was about consistency and quality. The assembly line allowed Ford to produce cars with a uniform standard, ensuring that every Model T that left the factory was reliable and built to last.

Ford’s vision extended beyond the assembly line itself. He recognized that to fully leverage the benefits of mass production, he needed to control the supply chain. This led to Ford’s adoption of vertical integration, a business strategy where a company owns and controls its suppliers, distributors, and retail outlets. By 1920, Ford had acquired mines, railroads, and even rubber plantations, ensuring a steady and cost-effective supply of raw materials for his factories. This control over the supply chain allowed Ford to further reduce costs and maintain a high level of quality in his products.

Another significant innovation Ford introduced was the concept of standardized parts. Prior to Ford, cars were often built with custom parts that were made to fit a specific vehicle. This made repairs difficult and expensive, as parts had to be individually crafted or modified. Ford’s use of standardized, interchangeable parts meant that components could be mass-produced and used in any vehicle of the same model. This not only reduced production costs but also made repairs easier and more affordable for consumers. The use of standardized parts became a key principle in manufacturing across various industries, further cementing Ford’s influence on modern production methods.

Ford’s innovations in manufacturing were closely tied to his approach to labor. In 1914, Ford shocked the business world by announcing that he would pay his workers $5 per day, more than double the prevailing wage for industrial labor at the time. This move, known as the “$5 workday,” was seen as radical and was met with skepticism from other industrialists. However, Ford understood that higher wages would lead to a more motivated and productive workforce. It also meant that his workers could afford to buy the cars they were producing, creating a virtuous cycle of production and consumption.

The $5 workday also had broader social implications. It helped to reduce labor turnover, which was a significant problem in the early 20th century. Before the wage increase, Ford’s factories had a high turnover rate, with many workers leaving after just a few months. The higher wages, combined with a shorter workday of eight hours, made Ford’s jobs highly desirable, attracting a stable workforce that was loyal and dedicated. This move not only improved productivity but also set a new standard for labor practices across the industry.

Ford’s influence on the automobile industry was not limited to manufacturing processes and labor practices. He also had a profound impact on automobile design and engineering. The Model T, often referred to as the “universal car,” was designed to be practical, durable, and easy to drive. It featured a simple, rugged design that could withstand the rough roads of rural America. The car’s high ground clearance, lightweight, and flexible suspension system made it ideal for the diverse terrain encountered by early drivers. The Model T’s reliability and ease of use made it incredibly popular, and it became the car of choice for millions of Americans.

In addition to the Model T, Ford introduced several other innovations that would become standard features in the automotive industry. He pioneered the use of vanadium steel in car production, a material that was stronger and lighter than the alternatives available at the time. This contributed to the durability and performance of Ford vehicles. Ford also introduced the concept of factory-backed financing, allowing customers to purchase cars on credit, which made automobiles more accessible to a broader audience.

Ford’s focus on innovation extended to the development of new production facilities. The River Rouge Complex, completed in the late 1920s, was a massive industrial site that epitomized Ford’s approach to manufacturing. The complex was designed to be a fully integrated production facility, where raw materials entered one end and finished vehicles rolled out the other. The River Rouge Complex included steel mills, glass factories, and assembly plants, all working in unison to produce cars efficiently and economically. It was the largest integrated factory in the world at the time and served as a model for future industrial complexes.

Despite his success, Ford was not without his critics. Some argued that his emphasis on efficiency and standardization stifled creativity and individuality in car design. Others pointed out that the working conditions in Ford’s factories, while better than many others at the time, could be harsh and demanding. The repetitive nature of assembly line work, combined with Ford’s strict management practices, led to significant worker dissatisfaction. However, Ford’s focus on innovation and efficiency cannot be denied. His contributions to the automobile industry laid the groundwork for the modern automotive world and influenced manufacturing practices in industries far beyond cars.

In summary, Henry Ford’s innovations in manufacturing, labor, and design transformed the automobile from a luxury item to an essential part of everyday life. His introduction of the moving assembly line revolutionized production, making cars affordable for the average person. His focus on vertical integration, standardized parts, and worker wages set new standards for industry practices. Ford’s legacy in the automobile industry is one of innovation, efficiency, and accessibility, and his influence continues to be felt in the modern world.

Impact on Society and the Economy

Henry Ford’s influence extended well beyond the confines of the automobile industry; his innovations had a profound and lasting impact on American society and the global economy. Ford’s introduction of the Model T and the assembly line not only transformed how products were manufactured but also fundamentally changed the way people lived and worked. The ripple effects of Ford’s innovations helped shape the 20th century and continue to influence the modern world.

One of the most significant societal impacts of Ford’s work was the democratization of the automobile. Before the Model T, cars were primarily luxury items owned by the wealthy. They were expensive, difficult to operate, and often unreliable. By making the automobile affordable and accessible to the average American, Ford revolutionized personal transportation. The Model T, with its simplicity, durability, and low cost, became the car of the people. Its widespread adoption marked a shift in American society, as the car became an integral part of daily life.

The widespread use of automobiles had far-reaching consequences for American society. The Model T gave people unprecedented mobility, allowing them to travel farther and faster than ever before. This newfound mobility had a transformative effect on American culture and the economy. It contributed to the growth of the suburbs, as people were no longer confined to living within walking distance of their workplaces. The car made it possible for people to live in suburban areas and commute to cities for work, leading to the expansion of urban areas and the development of new communities.

The rise of the automobile also led to significant changes in the American landscape. Roads, highways, and bridges were built to accommodate the growing number of cars, leading to the development of a vast and complex transportation infrastructure. The construction of the interstate highway system in the 1950s, inspired in part by the need to support automobile travel, further accelerated suburbanization and economic growth. The automobile also spurred the growth of related industries, including oil, steel, rubber, and glass, contributing to the overall expansion of the American economy.

Ford’s influence extended to the global economy as well. The success of the Model T and the assembly line made the United States a leader in industrial production and innovation. Ford’s manufacturing techniques were adopted by industries around the world, leading to increased productivity and economic growth on a global scale. The principles of mass production, which Ford perfected, became the foundation of modern industrial economies, driving economic development in countries across the globe.

Ford’s impact on labor practices was equally significant. The introduction of the $5 workday in 1914 was a landmark moment in American labor history. By doubling the wages of his workers, Ford not only improved their standard of living but also set a precedent for fair wages in the industrial sector. The $5 workday attracted thousands of workers to Ford’s factories, reducing turnover and increasing productivity. It also had a ripple effect throughout the economy, as other companies were forced to raise wages to compete for labor.

The $5 workday also had social implications. It helped create a new middle class in America, as factory workers who earned higher wages could now afford to buy homes, cars, and other consumer goods. This rise in disposable income contributed to the growth of consumer culture in the United States, with the automobile at its center. Ford’s workers, who were among the first to benefit from this new economic model, became some of the earliest participants in the mass consumer economy that would define the 20th century.

Ford’s approach to labor was not without its criticisms. While he paid his workers well, he also imposed strict controls on their behavior, both inside and outside the factory. The Ford Sociological Department, established to monitor workers’ lives, was responsible for ensuring that employees adhered to Ford’s moral standards. This included visits to workers’ homes to check on cleanliness, sobriety, and overall living conditions. While this paternalistic approach was intended to ensure a stable and productive workforce, it also drew criticism for its invasive nature. Many saw it as an overreach into the personal lives of workers, blurring the lines between employment and personal freedom. Ford’s strict policies reflected his belief in a disciplined, moral workforce, but they also highlighted the tensions between labor rights and employer control during the early 20th century.

Despite these criticisms, the overall impact of Ford’s labor policies was overwhelmingly positive. The higher wages and shorter workdays set new standards for the American workforce, contributing to the rise of the middle class. Ford’s practices also influenced other industries, as companies across the nation began to adopt similar wage policies to attract and retain workers. This helped to stabilize the labor market and reduce the frequency of strikes and labor unrest that had plagued the industrial sector in the late 19th and early 20th centuries.

Ford’s influence on society extended beyond the workplace. His success and wealth enabled him to pursue a variety of interests and causes, some of which had lasting effects on American culture and politics. For instance, Ford was a strong advocate for pacifism and opposed U.S. involvement in World War I. In 1915, he funded a “peace ship” expedition to Europe in an attempt to negotiate an end to the war. Although the mission was unsuccessful, it highlighted Ford’s commitment to peace and his willingness to use his resources to promote his beliefs.

Ford also played a role in shaping American education. In 1926, he established the Henry Ford Trade School, which offered vocational training to young men. The school was designed to provide students with practical skills that would prepare them for careers in industry. Ford believed that traditional education was too focused on academic subjects and that vocational training was essential for preparing students for the workforce. The Henry Ford Trade School was one of the first of its kind in the United States and served as a model for vocational education programs across the country.

Another significant aspect of Ford’s legacy is his impact on American agriculture. In the 1910s and 1920s, Ford was deeply interested in improving agricultural practices and increasing farm productivity. He believed that the principles of mass production could be applied to farming and that mechanization would lead to greater efficiency and higher yields. To this end, Ford developed a series of affordable tractors and other farm machinery that made it easier for farmers to cultivate their land. His efforts to modernize agriculture helped to increase food production and improve the standard of living for many rural Americans.

Ford’s impact on society and the economy was not without controversy. He was known for his anti-Semitic views, which were widely publicized in the 1920s through a series of articles in his newspaper, The Dearborn Independent. These articles, which were later compiled into a book titled The International Jew, promoted harmful stereotypes and conspiracy theories about Jewish people. Ford’s anti-Semitic views were condemned by many, and he eventually apologized for the articles in 1927. However, the damage to his reputation was significant, and his views have been a stain on his legacy.

Despite this, Ford’s contributions to society and the economy were immense. His innovations in manufacturing, labor practices, and business management helped to shape the modern world. The Model T and the assembly line made automobiles accessible to millions of people, transforming personal transportation and contributing to the growth of the American middle class. Ford’s impact on labor practices helped to improve the standard of living for workers and set new standards for wages and working conditions. His influence on agriculture, education, and other areas of society further demonstrated his commitment to improving the lives of ordinary people.

Ford’s legacy is also evident in the global economy. The principles of mass production and vertical integration that he pioneered have been adopted by industries around the world, leading to increased productivity and economic growth. Ford’s vision of affordable, reliable products for the masses has become a guiding principle for businesses across a wide range of industries. Today, the Ford Motor Company continues to be a major player in the global automotive industry, and Ford’s influence can be seen in the practices and philosophies of countless other companies.

In summary, Henry Ford’s impact on society and the economy was profound and far-reaching. His innovations in manufacturing and labor practices helped to transform the United States into a modern industrial economy and set new standards for business practices around the world. Ford’s legacy is a complex one, marked by both incredible achievements and significant controversies. However, his contributions to the development of modern society are undeniable, and his influence continues to be felt to this day.

Later Years and Legacy

As Henry Ford aged, his influence on the Ford Motor Company and the broader automobile industry began to wane. The 1920s and 1930s were a period of significant change for both Ford and his company. Although Ford had achieved remarkable success in the early years of the 20th century, the challenges of the Great Depression, increasing competition, and Ford’s own resistance to change tested the resilience of his legacy.

By the mid-1920s, the Ford Motor Company was facing increasing competition from other automakers, most notably General Motors (GM). GM, under the leadership of Alfred P. Sloan, introduced the concept of planned obsolescence and a wider range of models to appeal to different market segments. While Ford continued to produce the Model T, GM offered customers more choices, with different models and features that catered to varying tastes and incomes. This approach proved successful, and by 1927, GM had surpassed Ford in sales, marking a shift in the automotive industry.

Ford’s response to this competition was to finally discontinue the Model T in 1927, after producing more than 15 million units. The decision to end production of the Model T was a difficult one for Ford, as the car had been his crowning achievement and a symbol of his success. However, it was clear that the market had changed, and Ford needed to innovate to remain competitive. The company introduced the Model A later that year, which was a significant departure from the Model T in terms of design and features. The Model A was well-received and helped Ford regain some of its lost market share, but it was clear that the company could no longer dominate the industry as it once had.

During this period, Ford’s son, Edsel Ford, played an increasingly important role in the company. Edsel, who had been involved in the business since the early 1910s, had a more modern and sophisticated approach to management than his father. He was instrumental in the development of the Model A and advocated for the introduction of new models and features to keep up with consumer demand. However, Henry Ford’s dominant personality and reluctance to delegate authority often overshadowed Edsel’s contributions. The elder Ford was known for his stubbornness and resistance to change, which at times hindered the company’s ability to adapt to a rapidly evolving market.

The Great Depression, which began in 1929, had a severe impact on the Ford Motor Company, as it did on most businesses. Car sales plummeted, and the company was forced to cut production and lay off workers. Despite these challenges, Ford remained committed to his principles, refusing to cut wages or implement layoffs on the same scale as other companies. However, the economic downturn and Ford’s refusal to modernize his management practices led to a decline in the company’s profitability and market share.

The 1930s also saw increasing labor unrest at Ford’s factories. The rise of labor unions and the growing demand for workers’ rights led to a series of strikes and conflicts between workers and management. Ford, who had always been opposed to unions, resisted these efforts to organize his workers. The most notable of these conflicts was the Battle of the Overpass in 1937, when Ford’s security forces clashed with union organizers at the Rouge plant in Dearborn, Michigan. The violent confrontation received widespread media coverage and damaged Ford’s public image, portraying him as an opponent of workers’ rights.

Despite these challenges, Ford remained active in the company well into his later years. However, his health began to decline in the late 1930s, and Edsel took on more responsibility for the day-to-day operations of the business. Tragically, Edsel Ford died of stomach cancer in 1943 at the age of 49, a loss that deeply affected Henry Ford. With Edsel’s death, Henry Ford briefly resumed control of the company, but it was clear that he was no longer capable of managing the business effectively.

In 1945, Henry Ford II, Edsel’s son, took over as president of the Ford Motor Company. The younger Ford was tasked with modernizing the company and restoring its position in the industry. He brought in a new management team and implemented a series of reforms that helped to turn the company around. Under Henry Ford II’s leadership, the Ford Motor Company regained its status as a leading automaker, but the company’s culture and operations were significantly different from those established by his grandfather.

Henry Ford passed away on April 7, 1947, at the age of 83. His death marked the end of an era, but his legacy lived on through the Ford Motor Company and the countless innovations he introduced. Ford’s contributions to the automobile industry and manufacturing had a lasting impact on the world, and he is remembered as one of the greatest industrialists of the 20th century.

Ford’s legacy is a complex one, marked by both extraordinary achievements and significant controversies. On one hand, he revolutionized manufacturing and made automobiles accessible to the masses, transforming American society and the global economy. His innovations in mass production and labor practices set new standards for industry and contributed to the rise of the middle class. On the other hand, his anti-Semitic views and resistance to labor rights have cast a shadow over his reputation.

Today, Ford is remembered as a visionary who changed the world through his innovations and business acumen. The Ford Motor Company continues to be one of the largest and most successful automakers in the world, a testament to the enduring impact of Henry Ford’s work. His pioneering methods in manufacturing, particularly the assembly line, revolutionized industry not just in automobiles but across numerous sectors. His contributions to labor practices, including the introduction of the $5 workday, set new standards for worker compensation and conditions.

Ford’s legacy is also reflected in the broader impact of the automobile on society and the economy. His work helped to democratize personal transportation, influencing the development of suburbs, infrastructure, and global economic growth. Despite facing criticism for his anti-Semitic views and resistance to labor unions, the positive aspects of his legacy in terms of industrial innovation and the democratization of technology remain significant. Henry Ford’s life story is a complex one, marked by both groundbreaking achievements and controversies, but his influence on modern industry and society is undeniable.